We strive to create products that challenge established paradigms, taking advantage of new technologies and a team of highly specialized professionals committed to our mission.

We strive to create products that challenge established paradigms, taking advantage of new technologies and a team of highly specialized professionals committed to our mission.

At King Agro we have spent more than 20 years working in calculating and designing components and structures in Carbon Fiber. We have developed our own applications for Finite Method Analysis, which are verified on dozens of structures every year.

Annually, we invest 75% of our revenue in the development of manufacturing processes and new products. Our commitment to never-ending improvement is reflected in the processes of vacuum, lamination, autoclave and robot machining, all of which increase the quality of our products.

Somos

Once the design is finalized, there are 4 stages to be completed.

Prototyping

A prototype is built to assess feasibility and is subjected to destructive testing, and its design optimized.

Product Execution Study

the manufacturing process is analyzed and improvements in the design are made with the purpose of speeding up the manufacturing process.

Durability testing

A small batch of products are manufactured and tested on the field for approximately six months

Production launch

Finally, once all improvements are made, the final stage is reached. The product, thoroughly tested, is now ready to be launched

To reach this goal we employ a Quality Management System that perfectly adapts to the requirements of the Carbon Fiber sector, from the raw material acquisition to the market launch of a new product. Our Control Plan counts with rigorous quality controls from the conception of the product in the design phase all the way through to the delivery of the finished product to the client, and our Quality Control management model is based on Lean Manufacturing, with continuous follow-up indicators, using the DMAIC methodology and the Kaizen system.

We work closely with our providers assuring quality is maintained in all components, new projects, and research and development. At King Agro each manufacturing phase counts with the most advanced quality control instruments, assuring the functional, physical-mechanical and resistant characteristics to outdoor conditions, reaching a product compliant with the highest standards in Quality Control in the Carbon Fiber industry.

The resin with which the Carbon Fiber is impregnated cures at room temperature, which is why it must be stored in freezers with sub-zero temperatures.

The first step in the manufacturing process is cutting the Carbon Fiber sheets according to the required geometry using a CNC plotter. The cut-outs are positioned over the molds (produced at a 5-axis mechanization center), which are then subjected to vacuum so that all air between the Carbon Fiber layers is sucked out, and the sheets are completely compacted. The vacuum pressure is equivalent to an additional pressure bar (10.000 kg/m2).

The mold is then placed in the autoclave where three additional pressure bars are applied, reaching a pressure equivalent to 48 adult elephants stacked vertically. Simultaneously, the temperature inside the autoclave reaches 284°F, enough to fully polymerize the resin.

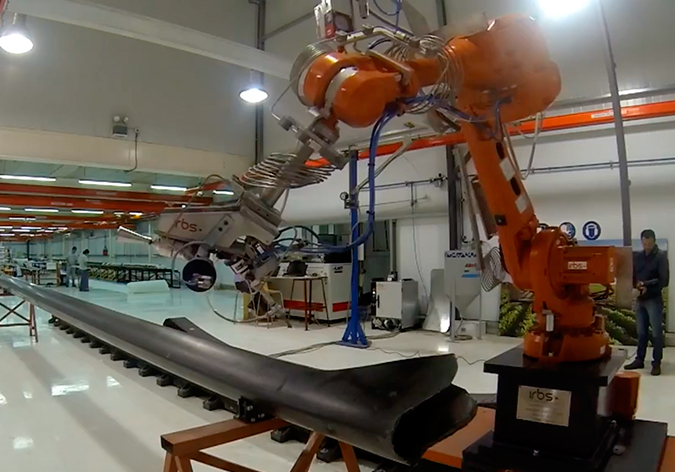

Holes, cut-outs and edges are then grinded by a CNC WaterJet robot.

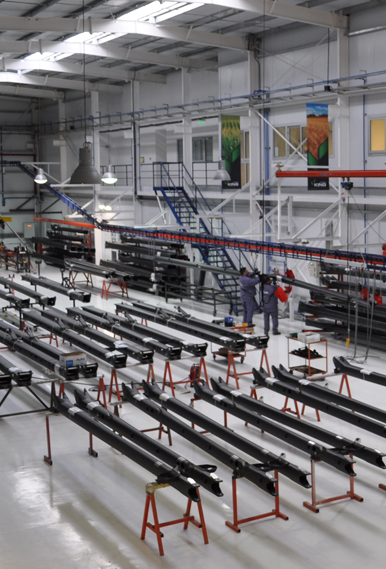

The boom is carried through the production line, where the parts are sanded and clear-coated with a polyurethane paint to avoid degradation (yellowing) of the resin. Finally, the boom is dried in a tunnel fitted with infrared lamps.

The Quality Control department is present at all stages of the process, assuring that the parts produced are within predefined tolerances. In order to accomplish this, measuring devices like the FaroArm are used.